Principles of Machining and Process Planning

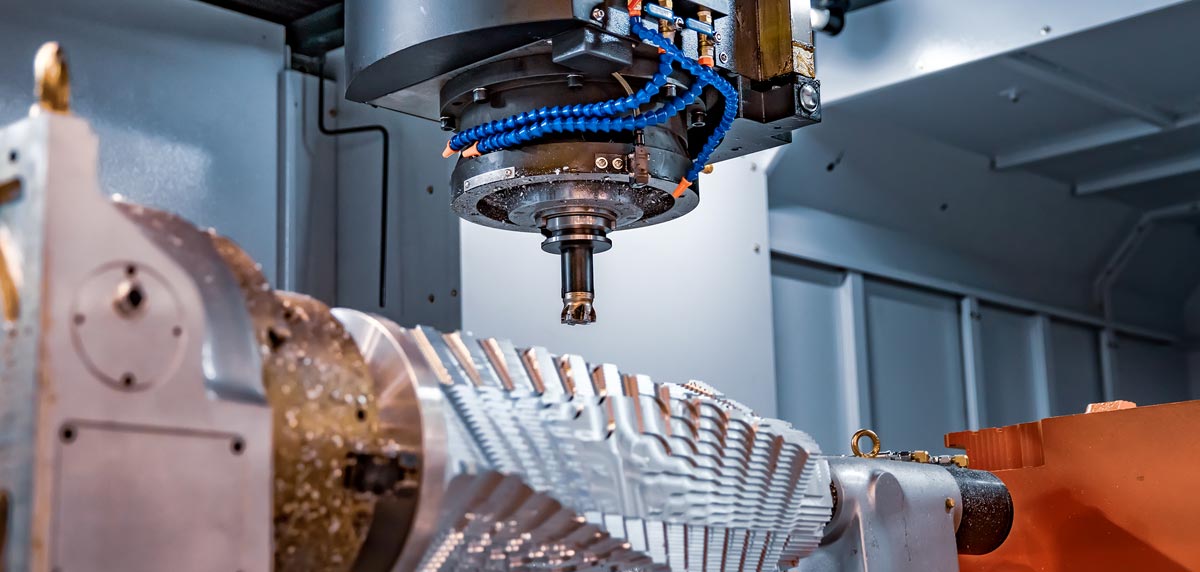

Introduction to machining processes

Chip removal machining processes are widely used in industry. In these processes, the size of the original part circumscribes the final geometry, and the excess material is removed in the form of chips. The amount of scrap ranges from a few percent to 70-90% of the original part.

Comparing this type of manufacturing with other methods to achieve the final geometry, advantages and disadvantages are included depending on the case.

Among the advantages of this type of machining process, which are the reasons why its use is so widespread, are:

- High dimensional accuracy is achieved in your operations

- They can make a wide variety of shapes

- It does not change the microstructure of the material, thus preserving its mechanical properties.

- Surface textures suitable for different designs are achieved

- They are processes that are easy to automate and are very flexible.

- Requires little preparation time

- Little variety of tools

On the other hand, it also has disadvantages compared to other manufacturing processes, especially those involving plastic deformation forming and casting:

- It generates waste material that is often not recyclable.

- They require greater processing energy

- Production times are high

- The size of the parts is limited to that allowed by the machine tool.

- They tend to be uneconomical when the batch size is very high.

If you want to know the entire machining process, we leave you the link to download the Ebook "Principles of Machining and Process Planning" by the author: Manuel Estrems Amestoy

1. General index

2. Introduction to machining processes

3. Cutting geometry

4. Shear forces

5. Temperature and wear

6. Tool Materials and Machinability

7. Surface roughness

8. Machining economy

9. Design and analysis of mooring tools

10.Manufacturing planning

11.1. Machining problems

12.Exam Questions

13.Bibliography